Polymer Systems

Technology Limited

Advanced Technologies

EPM Electronic Packaging Material - Silicone

EPM Electronic Packaging Material Product Listing

EPM-2410 » Low Volatility Silicone Elastomer

| Typical Properties | Average Result |

| Uncured: | |

| Appearance | Translucent |

| Viscosity, Part A | 62,000 cP (62,000 mPas) |

| Viscosity, Part B | 40,000 cP (40,000 mPas) |

| Work Time | 30 minutes |

| Cured: 15 minutes at 150°C (302°F) | |

| Durometer, Type A | 30 |

| Tensile Strength | 750 psi (5.2 MPa) |

| Elongation | 350% |

| Lap Shear Strength | 400 psi (2.8 MPa) |

| Volatile Content (1 hour at 275°C) | 0.5% |

| Moisture Absorption | 0.07% |

| Volume Resistivity | 1.0 X Ohm 10exp13 cm |

| Dielectric Strength | 580 V/mil (22.62 kV/mm) |

| Dielectric Constant, 100 Hz | 2.9 |

| Dielectric Constant, 1 kHz | 2.9 |

| Loss Tangent, 100 Hz | 0.0003 |

| Loss Tangent, 1 kHz | 0.0003 |

| Coefficient of Linear Expansion | 28 µm/(m°C) |

| Glass Transition Temperature (Tg) (-70°C to 200°C) | -117°C (-178.6°F) |

| Ionic Content, Na | < 6 ppm |

| Ionic Content, K | < 3 ppm |

| Ionic Content, Cl | < 6 ppm |

The above properties are tested on a lot-to-lot basis. Do not use as a basis for preparing specifications. Please contact NuSil Technology for assistance and recommendations in establishing particular specifications.

EPM-2420 » Low Volatility General Purpose Silicone Adhesive

| Typical Properties | Average Result |

| Uncured: | |

| Appearance* | Transparent |

| Viscosity, Mixed* | 2,600 cP (2,600 mPas) |

| Cured: 1 hour at 65°C (149°F) | |

| Specific Gravity* | 1.01 |

| Durometer, Type A* | 30 |

| Tensile Strength* | 425 psi (2.9 MPa) |

| Elongation* | 150% |

| Volatile Content (1 hour at 275°C) | 0.85% |

| Ionic Content, Cl | <2 ppm |

| Ionic Content, K | <1 ppm |

| Ionic Content, Na | <8 ppm |

*Properties tested on a lot-to-lot basis. Do not use the properties shown in this technical profile as a basis for preparing specifications. Please contact NuSil Technology for assistance and recommendations in establishing particular specifications.

EPM-2421 » Low Volatility Silicone Elastomer

| Typical Properties | Average Result |

| Uncured: | |

| Appearance | Transparent |

| Viscosity, Part A | 3,750 cP (3,750 mPas) |

| Viscosity, Part B | 2,700 cP (2,700 mPas) |

| Work Time | 3 hours |

| Tack-Free Time | 5 hours |

| Cured: 15 minutes at 15°C (302°F) | |

| Specific Gravity | 1.02 |

| Durometer, Type A | 50 |

| Tensile Strength | 850 psi (5.9 MPa) |

| Elongation | 90% |

| Lap Shear Strength | 250 psi (1.73 MPa) |

| Volatile Content (1 hour at 275°C) | 0.7% |

| Volume Resistivity | 8.5 X 10 exp14 |

| Dielectric Strength | 610 V/mil (24.0 kV/mm) |

| Dielectric Constant, 100 Hz | 2.8 |

| Dielectric Constant, 1 kHz | 2.8 |

| Loss Tangent, 100 Hz | 0.0003 |

| Loss Tangent, 1 kHz | 0.0004 |

| Coefficient of Linear Expansion (-150°C to -170°C) | 87µm/(m°C) |

| Coefficient of Linear Expansion (-70°C to 200°C) | 297µm/(m°C) |

| Glass Transition Temperature (Tg) | -116°C (-176.8°F) |

| Ionic Content, Na | <6 ppm |

| Ionic Content, K | <3 ppm |

| Ionic Content, Cl | <6 ppm |

Properties tested on a lot-to-lot basis. Do not use the properties shown in this technical profile as a basis for preparing specifications. Please contact NuSil Technology for assistance and recommendations in establishing particular specifications.

EPM-2422 » Low Volatility Silicone Elastomer

| Typical Properties | Average Result |

| Uncured: | |

| Appearance* | Transparent |

| Viscosity, Part A* | 3,600 cP (3,600 mPas) |

| Cured: 4 hours at 65°C (149°F) | |

| Specific Gravity* | 1.04 |

| Durometer, Type A* | 40 |

| Tensile Strength* | 650 psi (4.5 MPa) |

| Elongation* | 100% |

| Lap Shear Strength* (primed w/CF1-135) | 200 psi (1.4 MPa) |

| Coefficient of Linear Expansion | |

| Below Tg (-150° to -115°C) | 10 ppm/°C (10µm/m/°C) |

| Above Tg (-95°C to 250°C) | 490 ppm/°C (490µm/m/°C) |

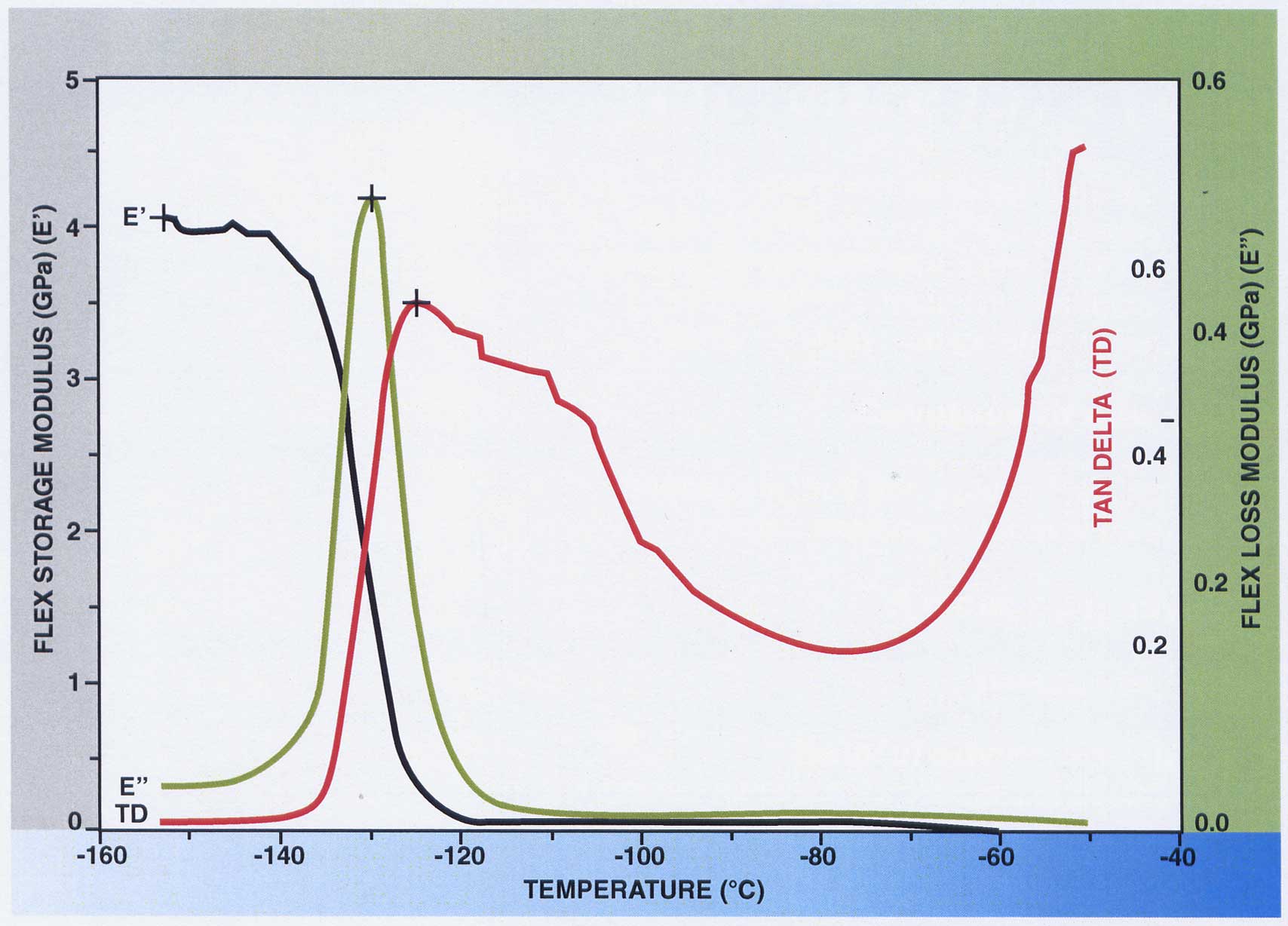

| Dynamic Mechanical Analysis (DMA) | See Product PDF for Graph |

| Volatile Content (1 hour at 275°C) | 0.2% |

| Ionic Content, Cl | <5 ppm |

| Ionic Content, K | < 1 ppm |

| Ionic Content, Na | < 1 ppm |

*Properties tested on a lot-to-lot basis. Do not use the properties shown in this technical profile as a basis for preparing specifications. Please contact NuSil Technology for assistance and recommendations in establishing particular specifications.

EPM-2423 » Silicone Elastomer

| Typical Properties | Average Result |

| Uncured: | |

| Appearance | Transparent |

| Viscosity, Part A | 8,000 cP (8,000 mPas) |

| Work Time | 2 hours |

| Tack-Free Time | 10 hours |

| Cured: 15 minutes at 150°C (302°F) | |

| Specific Gravity | 1.02 |

| Durometer, Type A | 50 |

| Tensile Strength | 1,000 psi (6.9 MPa) |

| Elongation | 125% |

| Cured: 4 hours at 60°C (140°F) | |

| Lap Shear Strength (primed w/ CF1-135) | 400 psi (2.8 MPa) |

Properties tested on a lot-to-lot basis. Do not use the properties shown in this technical profile as a basis for preparing specifications. Please contact NuSil Technology for assistance and recommendations in establishing particular specifications.

EPM-2461 » Low Volatility Static Dissipative Silicone Elastomer

| Typical Properties | Average Result |

| Uncured: | |

| Appearance, Part A | Black |

| Appearance, Part B | Translucent |

| Appearance, Mixed | Black |

| Viscosity, Part A | 1,250,000 cP (1,250,000 mPas) |

| Viscosity, Part B | 100,000 cP (100,000 mPas) |

| Work Time | 1 hour |

| Cured: 24 hours minimum at ambient temperature and humidity | |

| Durometer, Type A | 30 |

| Tensile Strength | 500 psi (3.4 MPa) |

| Elongation | 350% |

| Tear Strength | 30 ppi (5.3 kN/m) |

| Volume Resistivity | 535 ohm cm |

| Thermal Conductivity* | 0.223 W/(mK) |

| Volatile Content (1 hour at 275°C) | 0.78% |

| Ionic Content, Cl* | <5 ppm |

| Ionic Content, K* | <1 ppm |

| Ionic Content, Na* | <6 ppm |

*These properties NOT tested on a lot-to-lot basis. Please contact NuSil Technology for assistance and recommendations in establishing particular specifications.

Recommended Primer CF1-135

Note: Some bonding applications may require the use of a primer.

EPM-2462 » Low Volatility Electrically Conductive Silicone Elastomer

| Typical Properties | Average Result |

| Uncured: | |

| Appearance* | Tan, paste |

| Work Time* | 2.75 hours |

| Cured: 30 minutes at 150°C (302°F) | |

| Specific Gravity* | 3.39 |

| Durometer, Type A* | 85 |

| Tensile Strength* | 525 psi (3.6 MPa) |

| Volume Resistivity* | 0.005 ohm cm |

| Thermal Conductivity | 1.20 W/(mK)(29 x 10-4 cal/(cm sec°C)) |

| Coefficient of Linear Thermal Expansion | |

| Below Tg (-100°C to -50°C) | 140 ppm/°C (140µm/m/°C) |

| Above Tg (-30°C to 250°C) | 215 ppm/°C (215µm/m/°C) |

| Volatile Content (1 hour at 275°C) | 0.2% |

| Ionic Content, Cl | <5 ppm |

| Ionic Content, K | <7 ppm |

| Ionic Content, Na | <5 ppm |

*Properties tested on a lot-to-lot basis. Do not use the properties shown in this technical profile as a basis for preparing specifications. Please contact NuSil Technology for assistance and recommendations in establishing particular specifications.

Recommended Primer CF1-135

Note: Some bonding applications may require the use of a primer.

EPM-2463 » Low Volatility Electrically Conductive Rtv Silicone Elastomer

| Typical Properties | Average Result |

| Uncured: | |

| Appearance* | Green-gray |

| Flow, Base* (0.375" plunge for 30 seconds, mix vigorously for 5 minutes prior to testing) | 4 inches (10.2 cm) |

| Work Time* | 2.5 hours |

| Cured: 7 days minimum at ambient temperature and humidity | |

| Specific Gravity* | 3.23 |

| Durometer, Type A* | 75 |

| Tensile Strength* | 300 psi (2.1 MPa) |

| Elongation* | 70% |

| Tear Strength* | 55 ppi (9.7 kN/m) |

| Lap Shear Strength* (primed w/ SP-120) | 185 psi (1.3 MPa) |

| Volume Resistivity* (at 200±5°C) | 0.003 ohm cm |

| Thermal Conductivity | 1.5 W/mK (36 x 10-4 cal/(cm sec°C)) |

*Properties tested on a lot-to-lot basis. Do not use the properties shown in this technical profile as a basis for preparing specifications. Please contact NuSil Technology for assistance and recommendations in establishing particular specifications.

EPM-2480 » Dielectric Silicone Gel

| Typical Properties | Average Result |

| Uncured: | |

| Appearance* | Transparent |

| Viscosity* (tested within 15 minutes after catalyzation) | 2,500 cP (2,500 mPas) |

| Work Time* | >30 hours |

| Cured: 30 minutes at 150°C (302°F) | |

| Penetration* (GCA Penetrometer, 19.5 g shaft, 6.35 mm diameter, 5 seconds) | 4 mm |

| Volume Resistivity | 1 x 1014 ohm cm |

| Volatile Content (1 hour at 275°C) | 1.09% |

| Ionic Content, Cl | < 5 ppm |

| Ionic Content, K | <1 ppm |

| Ionic Content, Na | < 2 ppm |

*Properties tested on a lot-to-lot basis. Do not use the properties shown in this technical profile as a basis for preparing specifications. Please contact NuSil Technology for assistance and recommendations in establishing particular specifications.

Recommended Primer CF1-135

Note: Some bonding applications may require the use of a primer.

EPM-2481 » Dielectric Silicone Gel

| Typical Properties | Average Result |

| Uncured: | |

| Appearance* | Transparent |

| Viscosity, Part A* | 16,000 cP (16,000 mPas) |

| Viscosity, Part B* | 8,500 cP (8,500 mPas) |

| Viscosity, Mixed* | 18,000 cP (18,000 mPas) |

| Cured: 30 minutes at 150°C (302°F) | |

| Penetration* (Labline Penetrometer, 19.5 gram shaft, 1/4 inch foot, 5 seconds) | 0.4 mm |

| Volume Resistivity | 1 x 1014 ohm cm |

| Volatile Content (1 hour at 275°C) | 0.8% |

| Ionic Content, Cl | < 5 ppm |

| Ionic Content, K | < 1 ppm |

| Ionic Content, Na | < 2 ppm |

*Properties tested on a lot-to-lot basis. Do not use the properties shown in this technical profile as a basis for preparing specifications. Please contact NuSil Technology for assistance and recommendations in establishing particular specifications.

EPM-2482 » Low Volatility Dielectric Silicone Gel

| Typical Properties | Average Result |

| Uncured: | |

| Appearance* | Transparent |

| Viscosity* | 1,800 cP (1,800 mPas) |

| Cured: 40 minutes at 150°C (302°F) | |

| Penetration* (GCA Penetrometer, 19.5 g shaft, 6.35 mm diameter, 5 seconds) | 3 mm |

| Volatile Content (1 hour at 275°C) | 0.3% |

| Ionic Content, Cl | <5 ppm |

| Ionic Content, K | <1 ppm |

| Ionic Content, Na | <4 pmm |

*Properties tested on a lot-to-lot basis. Do not use the properties shown in this technical profile as a basis for preparing specifications. Please contact NuSil Technology for assistance and recommendations in establishing particular specifications.

Recommended Primer CF1-135

Note: Some bonding applications may require the use of a primer.

EPM-2490 » Low Volatility Thermally Conductive Silicone Adhesive

| Typical Properties | Average Result |

| Uncured: | |

| Appearance | White |

| Work Time | 2 hours |

| Tack-Free Time | 4.5 hours |

| Cured: | |

| Specific Gravity | 1.53 |

| Durometer, Type A | 75 |

| Tensile Strength | 200 psi (1.4 MPa) |

| Elongation | 30% |

| Lap Shear Strength | 160 psi (1.1 MPa) |

| Thermal Conductivity | 1.49 W/mK (36 x 10-4 cal/cmsec°C) |

| Volatile Content (1 hour at 275°C) | 0.2% |

| Moisture Absorption | 610% |

| Dielectric Strength | 610 V/mil (24.0 kV/mm) |

| Dielectric Constant, 100 Hz | 3.4 |

| Dielectric Constant, 1 kHz | 3.4 |

| Loss Tangent, 100 Hz | 0.002 |

| Loss Tangent, 1 kHz | 0.001 |

| Coefficient of Linear Expansion (-70°C to 200°C) | 240µm/(m°C) |

| Glass Transition Temperature (Tg) | -127°C (-196.6°F) |

| Ionic Content, Na | <3 ppm |

| Ionic Content, K | <3 ppm |

| Ionic Content, Cl | <6 ppm |

Properties tested on a lot-to-lot basis. Do not use the properties shown in this technical profile as a basis for preparing specifications. Please contact NuSil Technology for assistance and recommendations in establishing particular specifications.

Recommended Primer CF1-135

Note: Some bonding applications may require the use of a primer.

EPM-2491 » Low Volatility Thermally Conductive Silicone Adhesive

| Typical Properties | Average Result |

| Uncured: | |

| Appearance* | White |

| Viscosity, Part A* | 900,000 cP (900,000 mPas) |

| Tack-Free Time* | 4 hours |

| Work Time* | 2 hours |

| Cured: 4 hours at 65°C (149°F) | |

| Specific Gravity* | 1.45 |

| Durometer, Type A* | 75 |

| Tensile Strength* | 250 psi (1.7 MPa) |

| Elongation* | 60% |

| Tear Strength* | 55 ppi (9.7 kN/m) |

| Moisture Absorption, % gain after 168 hour exposure at 85°C (185°F) / 85% R.H. | 0.03% |

| Cured: 30 minute at 150°C (302°F) | |

| Thermal Conductivity* | 1.11 W/(mK)(26 x 10-4 cal/(cm sec°C)) |

*Properties tested on a lot-to-lot basis. Do not use the properties shown in this technical profile as a basis for preparing specifications. Please contact NuSil Technology for assistance and recommendations in establishing particular specifications.

EPM-2850 » Low Volatility RTV Silicone Adhesive

| Typical Properties | Average Result |

| Uncured: | |

| Appearance* | Translucent |

| Viscosity | 7,400 cP |

| Tack Free Time | 50 minutes |

| Cured: 7 days minimum @ ambient temperature and humidity | |

| Specific Gravity* | 1.01 |

| Durometer, Type A* | 16 |

| Tensile Strength* | 80 psi (0.55 MPa) |

| Elongation* | 200% |

| Volatile Content (1 hour at 275°C)* | 0.7% |

| Dielectric Strength* | 660 V/mil (25.8 kV/mm) |

*Properties tested on a lot-to-lot basis. Do not use the properties shown in this technical profile as a basis for preparing specifications. Please contact NuSil Technology for assistance and recommendations in establishing particular specifications.

Recommended Primer SP-120

Note: Some bonding applications may require the use of a primer.

EPM1-2493 » Low Volatility Silicone Elastomer

| Typical Properties | Average Result |

| Uncured: | |

| Appearance* | White |

| Viscosity, within 15 minutes of catalyzation* | 36,000 cP (36,000 mPas) |

| Viscosity, 2 hours after catalyzation* | 50,000 cP (50,000 mPas) |

| Tack-Free Time* | 13 hours |

| Cured: 15 minutes at 150°C (302°F) | |

| Specific Gravity* | 2.34 |

| Durometer, Type A* | 65 |

| Tensile Strength* | 180 psi (1.2 MPa) |

| Elongation* | 50% |

| Lap Shear Strength (primed with SP-270)* | 120 psi (0.8 MPa) |

| Thermal Conductivity* | 0.95 W/(mK)(23 x 10-4 cal/(cm sec°C)) |

| Volatile Content (1 hr at 275°C) | 0.35 % |

| Volume Resistivity | 3.4 X1013 |

| Dielectric Strength | 465 V/mil (18.1 kV/mm) |

| Dielectric Constant, 100 Hz | 4.9 |

| Dielectric Constant, 1 kHz | 4.9 |

| Dissipation Factor, 100 Hz | 0.003 |

| Dissipation Factor, 1 kHz | 0.002 |

| Coefficient of Linear Expansion (-70°C to 200°C) | 200µm/(m°C) |

| Glass Transition Temperature (Tg) | -98°C |

| Ion Content, Na | < 6ppm |

| Ion Content, K | < 3ppm |

| Ion Content, Cl | < 5ppm |

*Properties tested on a lot-to-lot basis. Do not use the properties shown in this technical profile as a basis for preparing specifications. Pleasecontact NuSil Technology for assistance and recommendations in establishing particular specifications.

Recommended Primer SP-270

Note: Some bonding applications may require the use of a primer.

Electronic Packaging Materials

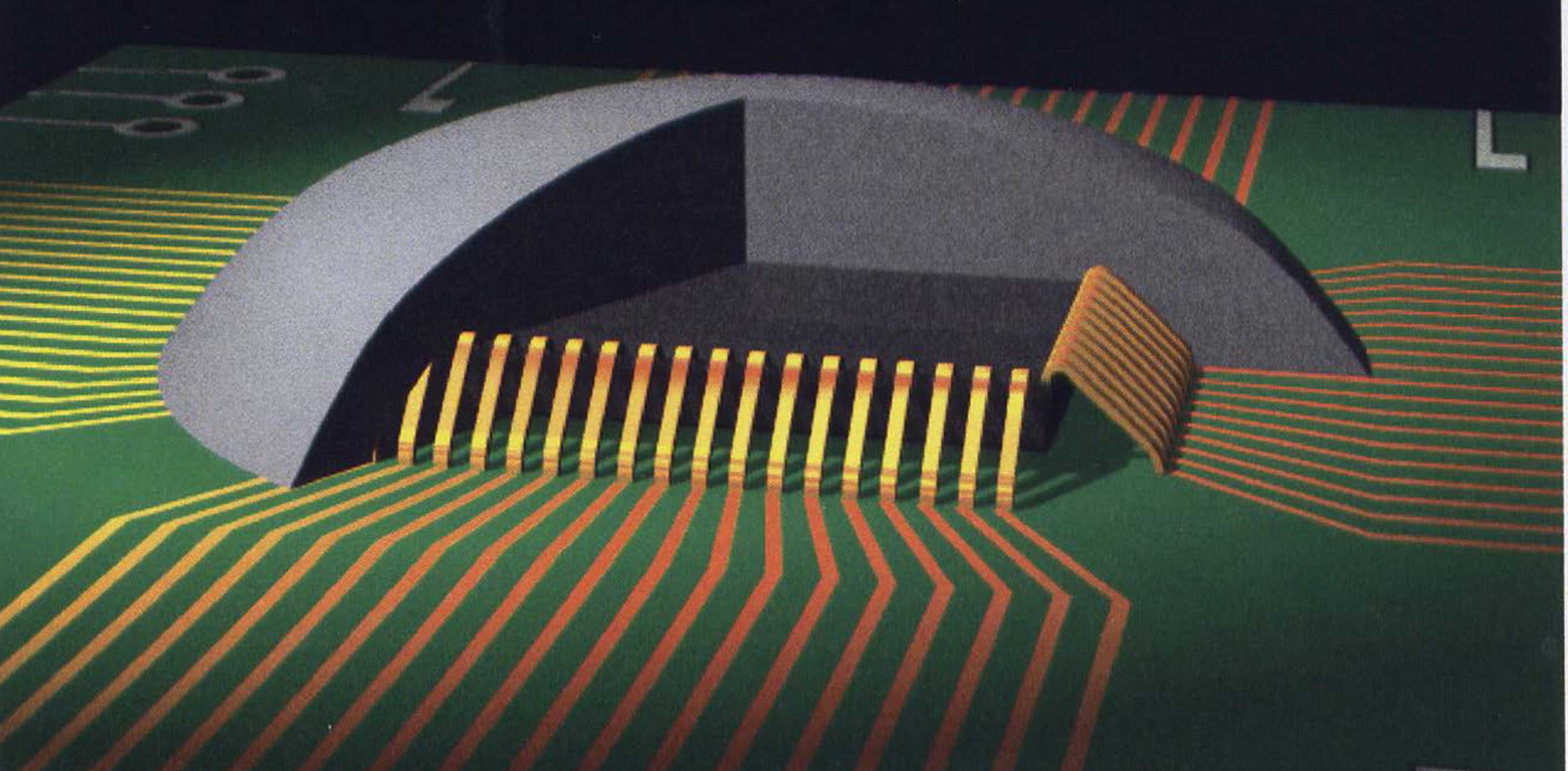

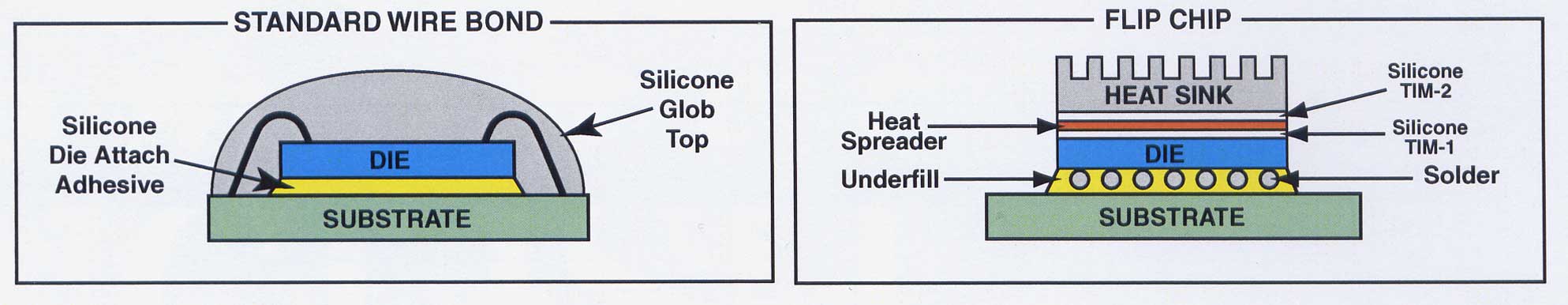

A low stress alternative for advanced electronic packaging, NuSil Technology's Electronic Packaging Materials (EPMs) allow the designer to choose from a unique line of silicones for various levels of packaging. Packaging options include a variety of products from Flip Chip Under Fill to Glob Top.

Silicone's unique chemical composition compared to organic based polymers applies lower shear stress on components during heating and cooling. Lower applied shear stress can be used in applications where hybrid packages utilize materials with various Coefficients of Thermal Expansion (CTE). Silicones offer stress relief during thermal cycling.

Benefits Of Silicone As Electronic Packaging Material

- Low Moisture Absorption, <0.4%

- Dielectric Strength, > 500V/mil (0.001 inch) or 20 kV/mm

- Thermal Stability, -115 °C to 260 °C

- Low Modulus

- Low Shrinkage, <1%

- Low Ionic Content (Na, K, Cl and NH3)

- Low Outgassing, <1% at 1 hr @ 275°C

- Available as gels, elastomers and greases

Contamination

Silicone adhesives have had a reputation over the years of "contaminating" surrounding areas with silicone oils while the device is in operation. NuSil Technology has addressed this by designing products in our EPM product line to introduce minimal contamination by the following criteria:

- Contain low concentrations of silicone oils: < 1 % Weight Loss when heated 1 hour at 275 °C.

- Low Ion Content: < 20 ppm of individual Na, K and Cl ions per MILSTD 883E.

- Addition Cure Mechanism: This cure mechanism has minimal shrinkage and does not produce chemical by-products, such as acids or alcohols that can affect components in assemblies.

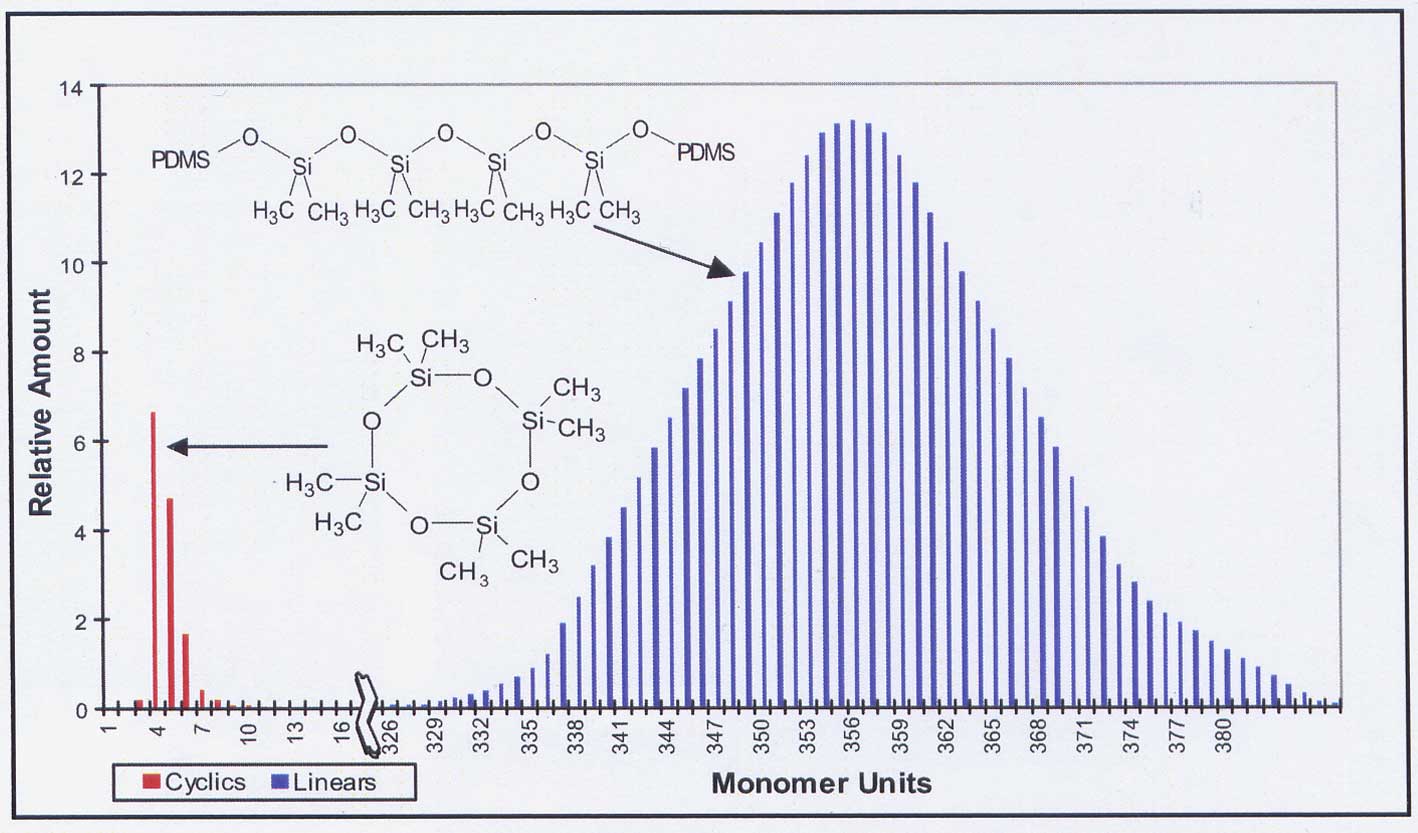

Silicone "oils" are low molecular weight silicones generated during the production of silicone polymers. The polymerization reaction often begins with polyorganosiloxane rings(A.K.A.cyclics) reacting with short chain siloxane species that act as chain terminators in the presence of an acid or base catalyst. The reaction is thermodynamically controlled and the concentration of the various chemical species produced is allowed to reach equilibrium over time. The chemical species produced during this reaction are a range of molecular weights of linear and cyclic compounds. Heat and vacuum are applied and the low molecular weight species can be removed. NuSil Technology has been performing this technique, known as "Wiped Film Evaporation" for the Aerospace industry for 30 years and are experts in this technology.

|

||||

|

|

|

|

|

Stress

Silicones have very low Glass Transition Temperatures (Tg) and low Elastic Modulus compared to other organic polymers. There are organic polymers that may have more than one Tg, which can apply stress on sensitive parts during temperature cycling or possessing. The Tg of a typical dimethylsilicone is —65 °C which allows the silicone to maintain its elasticity over large temperature ranges. Even when filled up to 85% (w/w) with ceramic or metallic fillers, the Tg is < —30 °C.

Silicone does have a high Coefficient of Thermal Expansion (CTE) but has an order of magnitude lower Elastic (Storage) Modulus compared to other organic polymers. The lower modulus allows stress relief during thermal cycling that can prevent warping, bending and shearing of sensitive parts within the device.

Inhibition

EPM Gels, Elastomers and Adhesives are designed to provide excellent optical, thermal and mechanical properties. However, some ingredients commonly found in certain adhesives, plastics and elastomers can adversely affect the cure chemistry in these products. NuSil recommends that adhesives, plastics and elastomers be analyzed for cure inhibition prior to selecting the silicone material for use. This evaluation should include materials used in any transfer containers, dispensing hoses, or utensils that come in direct contact with the gel components.

Processing Highly Filled Silicones

Electrical and thermally conductive silicones typically contain dense ceramic or metallic fillers that can settle over time. Prior to mixing Part A and B together, it is recommended to stir the individual Part A and B that contain the dense fillers to ensure the fillers are homogeneously dispersed prior to use. A vacuum chamber should be used to remove the air introduced during mixing. When working with equipment at reduced pressures, ensure container and chamber are rated to withstand the supplier's recommended operational pressure. Before getting started, reference the Material Certification for "Work Time" or other pot life parameters to determine curing time between mixing and applying to application. Place mixed material into appropriate container and fill approximately one quarter of the container's total volume to allow material to rise. It is recommended to slowly apply vacuum up to approximately 28 inches of Mercury (0.95 Barr). Hold vacuum until bubbles are no longer observed forming. Breaking the seal while pulling vacuum will allow bubbles to burst; expediting the process. It is not recommended to remove air via centrifuging from silicones with fillers having a specific gravity > 1. Centrifuging can be used for silicones that do not contain dense fillers.

Improving Adhesion

Since many substrates are difficult to bond to, the surface of the substrate must be modified to allow good wetting of the adhesive to allow chemical and mechanical interaction. Many substrates need to have the surface "activated" to enhance the adhesive's bond to the substrate. There are, in general, four typical techniques that can be used to improve the adhesive bond; primers, plasma, corona and flame treatment. These surface treatments can greatly enhance the adhesive bond and the type of treatment is dependent on configuration complexity, silicone adhesive and substrates. Adhesion is a very complex subject that incorporates principles from several scientific disciplines that are beyond the scope of this discussion.

Biomaterials

Advanced Technologies

Tubing

Equipment